Top 14 benefits of using an automated tool changer

Automatic tool changers are a great way to increase productivity, reduce machine downtime and improve overall efficiency. Here are the

Top 14 benefits of using an automated tool changer:

1. Reduce Machine Downtime

The most significant benefit of using an automatic tool changer is the reduction of downtime caused by changing tools manually.

The average time it takes to change tools manually is about 15 minutes per change, which adds up over time. With an automatic tool changer, you can reduce that time by as much as 80 percent.

2. Increase Productivity & Efficiency

Producing more parts per shift is another clear benefit of using an automatic tool changer. An automation device will allow operators to focus on other tasks while the machine performs its work.

This frees up their time so they can handle other duties around the shop or office instead of just standing around waiting for a machine to cycle through its subsequent operation.

3. Create Consistent Part Quality

Consistent part quality is another benefit of using an automatic tool changer, especially for small or unique parts requiring special tools for production.

Having these tools available always means operators can produce consistent results without worrying about whether a particular device will be available when needed.

4. Change Multiple Tools Automatically, At One Time

You can change multiple tools at once with an automatic tool changer. This is because the machine has a magazine made up of various stations where you can store the different tools needed for your operation. This makes it fast and easy to get everything set up so that you can start working immediately.

5. Change Tools without Operator Intervention

An automatic tool changer is a great way to save time and increase productivity if you need to change tools frequently during your operation.

With this type of machine, you don't need anyone around to help with the changing process — all you do is insert the new tool into place and press start! The rest takes place automatically.

6. Reduce Errors and Tool Breakage

With an automatic tool changer, you can eliminate human error by eliminating the need for operators to manually remove tools from a magazine and hand them to the operator at the machine.

This helps ensure that each tool is used only once and returned to its proper location in the magazine.

7. Automatic Changeover

The most crucial step to increasing your productivity is the automatic changeover. This allows you to reduce your changeover time and increase machine utilization by at least 30%.

8. Semi-Automatic Changeover

Semi-automatic changeovers are ideal for companies that need to change over their machines once or twice per day. This can be done using an operator or a simple manual system.

9. Manual Changeover

This option is typically used by companies with low-volume production, which means they only make products once in a while or don't need to make small batches of parts.

Manual changeovers are also ideal for companies that don't have the resources to invest in semi-automatic systems or those who prefer not to use automation.

10. Improve Cycle Time

An automatic tool changer can improve cycle time by up to 50%. This means that instead of taking 15 minutes to change tools on a machine, it takes less than 3 minutes. This is because manually changing tools often involves several steps, including:

• Remove the old device from the spindle (levering or pressing).

• Insert the new tool into the spindle (levering or stuffing).

• Set correct tool height on the spindle (pressing).

• Change position of the workpiece (manual operation).

These steps can be eliminated with an automatic tool changer, which reduces time spent on each cycle and improves productivity.

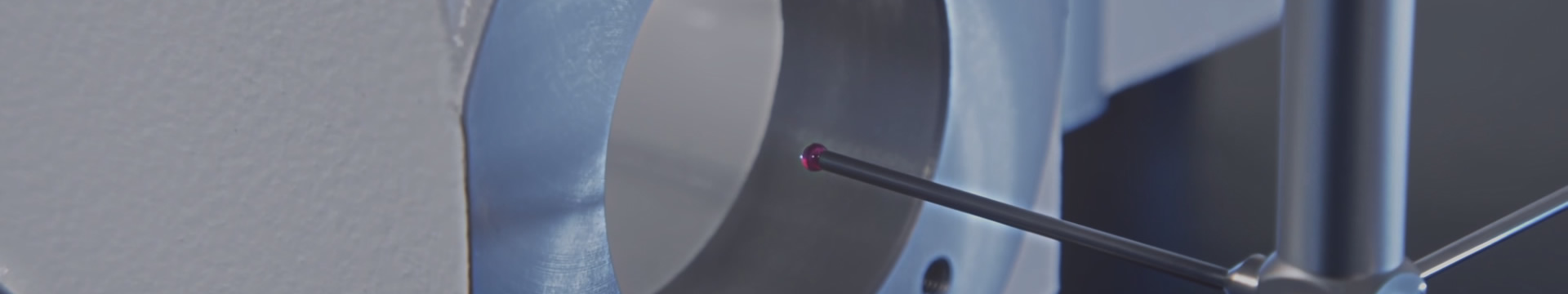

11. Increase Spindle and Tool Life

An automatic tool changer reduces wear on your machine's spindle and its tools by minimizing manual handling and eliminating human error. With this reduction in wear comes longer tool life and increased spindle life.

12. Eliminate Manual Tool Changes

Manual tool changes are a leading cause of lost production time and quality issues. For example, if a mistake is made while changing between tools, the operator may have to re-machining the workpiece before starting again. The time wasted on re-machining can be expensive, especially for large batches or long runs.

13. Protect Workholding Systems and Product Quality

Automated tool changers can help eliminate manual tool changes and protect your work holding systems from damage caused by repeated manual handling of tools.

Automatic tool charging systems can also help protect product quality by ensuring that each component is machined to specifications every time it passes through your machine center.

14. Improve Product Consistency (Reduced Variation)

Automatic tool changers can help reduce variation in product quality by ensuring that every part produced is identical.

This can be done using one automatic tool changer, which can store multiple tools for each part, or multiple automatic tool changers, each with a single tool.

Where Should You Buy Automatic Tool Chargers?

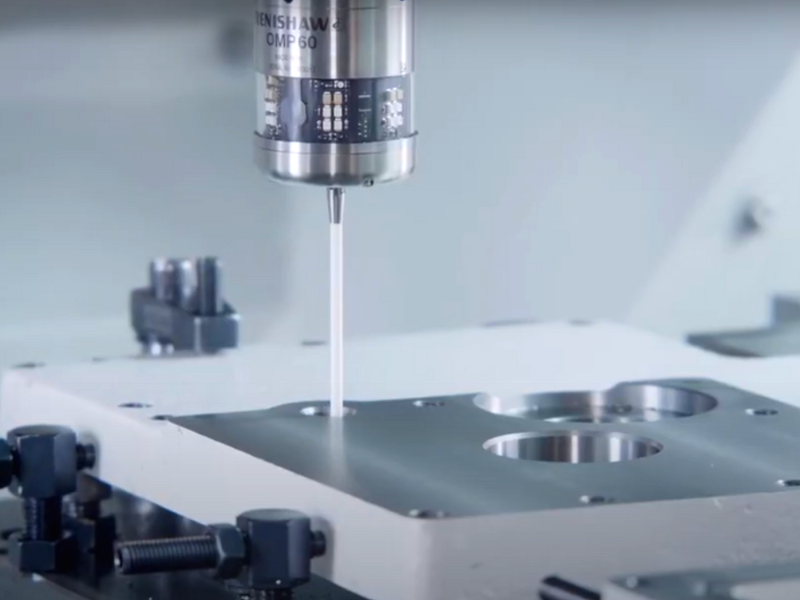

The automatic tool changers are available in different types depending on their functionality and features.

Some can be used for one specific task, while others can be used for multiple tasks simultaneously. The best automatic tool charger ATC website is GIZIN, which provides high-quality products at affordable prices.

It works with milling cutters, turning tools, thread mills, drill bits, broaching tools, and much more. The tool changer can hold up to 8 different devices simultaneously, so you can switch out between jobs quickly!

Contact us for more information!