The Evolution of Automotive Manufacturing: Embracing Advanced Technologies for Increased Efficiency

Introduction

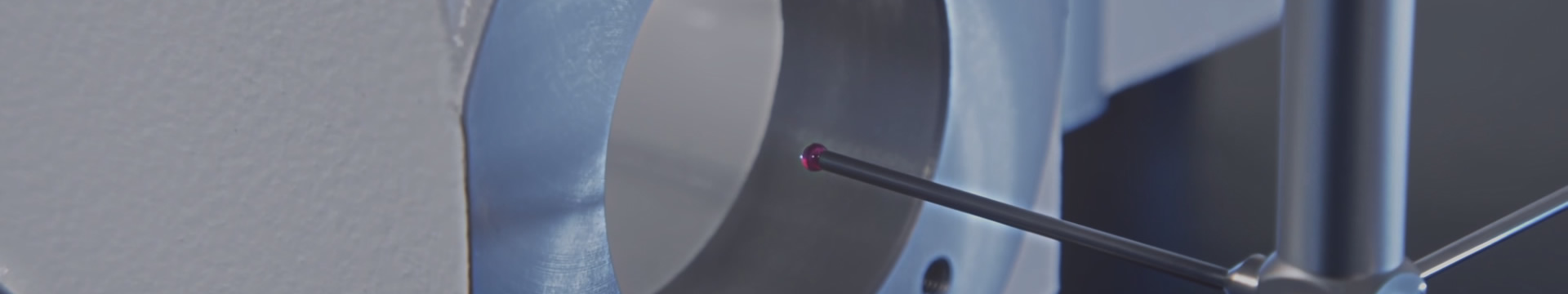

In recent years, the automotive manufacturing industry has seen significant changes, driven by the adoption of advanced technologies to enhance production efficiency, quality, and flexibility. One such technological advancement is the use of Automatic Tool Changer (ATC) Camboxes in CNC (Computer Numerical Control) machines. These devices play a crucial role in the production of vehicle components, offering numerous benefits that align with the current trends in automotive manufacturing.

The Role of ATC Camboxes in Automotive Manufacturing

ATC Camboxes are designed to automatically switch between different tools in CNC machines, enabling continuous production without manual intervention. This capability is particularly beneficial in the automotive industry, where the demand for precision and high-volume production is paramount. By integrating ATC Camboxes, automotive manufacturers can achieve:

- Increased Production Speed: ATC Camboxes significantly reduce the downtime associated with manual tool changes, allowing for faster production cycles and higher throughput.

- Enhanced Precision and Quality: Automated tool changes ensure that the correct tool is used for each specific task, maintaining high precision and consistent quality across all manufactured components.

- Flexibility in Production: With the ability to quickly switch between different tools, ATC Camboxes enable manufacturers to easily adapt to changing production requirements, whether it’s a shift in design or a need for customization.

Current Trends in Automotive Manufacturing

The automotive industry is undergoing several key trends that are shaping the future of vehicle production. These trends highlight the importance of adopting advanced technologies like ATC Camboxes:

- Automation and Robotics: The integration of automation and robotics in production lines is increasing, aimed at improving efficiency and reducing human error. ATC Camboxes are a critical component of this trend, facilitating seamless operations in automated CNC machines.

- Electric Vehicles (EVs): The rise of electric vehicles has brought new challenges and opportunities in manufacturing. Producing components for EVs requires precise machining and flexibility to accommodate different designs, which ATC Camboxes can efficiently provide.

- Customization and Flexibility: Consumers are demanding more customized vehicles. ATC Camboxes allow manufacturers to quickly switch tools and produce a variety of parts without significant downtime, supporting this trend towards personalization.

- Sustainability: There is a growing focus on sustainable manufacturing practices. ATC Camboxes contribute by reducing waste and improving energy efficiency, as automated systems can be optimized for minimal resource usage.

GIZIN’s Contribution to Automotive Manufacturing

GIZIN, a leader in ATC Cambox technology, has been instrumental in advancing the capabilities of ATC Camboxes to meet the evolving needs of the automotive industry. Their ATC Cambox systems are designed for high performance, reliability, and integration with modern CNC machines, making them ideal for automotive applications. Some of the key features and benefits of GIZIN’s ATC Cambox systems include:

- Robust Design: GIZIN’s ATC Camboxes are built to withstand the demanding conditions of automotive manufacturing, ensuring long-term durability and consistent performance.

- High-Speed Operation: Designed for rapid tool changes, GIZIN’s ATC Camboxes enhance production speed, helping manufacturers meet tight deadlines and high-volume demands.

- Precision Engineering: With advanced control systems, GIZIN’s ATC Camboxes maintain the highest levels of precision, crucial for the production of intricate and high-quality vehicle components.

- Adaptability: GIZIN’s ATC Camboxes are compatible with a wide range of CNC machines, providing flexibility and ease of integration into existing production lines.

Conclusion

The automotive manufacturing industry is rapidly evolving, driven by trends towards automation, customization, and sustainability. Automatic Tool Changer (ATC) Camboxes are at the forefront of this transformation, offering significant advantages in terms of production speed, precision, and flexibility. GIZIN’s innovative ATC Cambox solutions are perfectly aligned with these trends, providing the automotive industry with the tools needed to stay competitive and meet the demands of modern vehicle production. As the industry continues to embrace advanced technologies, the role of ATC Camboxes will only become more critical, paving the way for a more efficient and dynamic manufacturing future.